SOLUTIONS

Computational Fluid Dynamics (CFD)

With the ever increasing need to enhance the commercial viability of complex industrial projects, the requirement to optimise capital expenditures on process improvements has become of paramount importance. Backed by MES’ expertise in Technical Safety, Risk Management and Asset Integrity, CFD forms part of a fully integrated package of services that can provide vital insight into industrial processes and operations, helping to make suitable decisions to boost business performance.

What is Computational Fluid Dynamics?

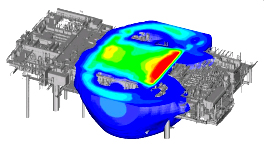

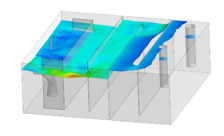

Blast wave propagation following vapour cloud explosion on a large offshore platform

Computational Fluid Dynamics (CFD) is a powerful numerical tool that solves complex three-dimensional problems faced by the Oil and Gas Industry, involving fluid dynamics, multiphase flow, conjugate heat transfer, combustion, radiation and any other physical processes. As a result of the continuous improvement in computer science, CFD has become an indispensable design instrument that can now meet commercial project schedules.

Blast wave propagation following vapour cloud explosion on a large offshore platform

Computational Fluid Dynamics (CFD) is a powerful numerical tool that solves complex three-dimensional problems faced by the Oil and Gas Industry, involving fluid dynamics, multiphase flow, conjugate heat transfer, combustion, radiation and any other physical processes. As a result of the continuous improvement in computer science, CFD has become an indispensable design instrument that can now meet commercial project schedules.

The best available hardware and well-established CFD software packages (such as ANSYS CFD, Star-CCM+, KFX, FLACS) are used to provide accurate and rapid design solutions.

How can CFD help your business?

Key CFD applications offered by MES include:

- Rigorous consequence modelling of major accident hazards, flare, controlled venting and exhaust;

- Flow assurance studies to ensure reliable, efficient and safe transport of produced fluids;

- Process analyses for troubleshooting and design verification.

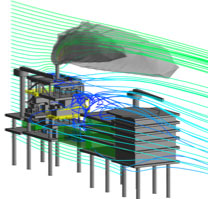

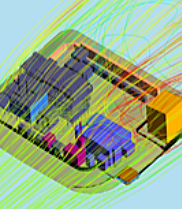

Airflow streamlines and turbine exhausts on bridge-linked offshore facilities

Airflow streamlines and turbine exhausts on bridge-linked offshore facilities

Technical Safety CFD Capabilities

MES offers in depth expertise utilising CFD for consequence modelling and combining results with standard Technical Safety studies, such as QRA, EERA or F&G Mapping. Typical CFD applications include:

- Natural / forced ventilation

- Toxic / flammable gas dispersion

- Vapour / dust cloud explosion and blast wave propagation

- Probabilistic explosion exceedance analysis

- Hot plume exhaust and cold vent

- Helideck environment

- Hydrocarbon fires and smoke propagation

- Flare radiation

- Subsea plume dispersion

Process CFD Capabilities

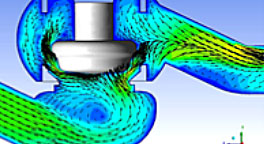

Typical process CFD applications, generally for troubleshooting and design verification, include:

- Water hammer effects and heat exchanger burst tubes

- Flow-induced vibration

- Minimum metal design temperature

- Optimisation of internal flow units (e.g. WHRUs, incinerators...)

Flow across a valve

Flow across a valve

Flow Assurance CFD Capabilities

MES has extensive experience in multiphase flow analysis of complex and challenging hydrocarbon transport problems. Typical CFD applications include:

- Erosion / Corrosion

- Sand accumulation

- Condensation formation

- Separation and slug catcher

- Multiphase pipe flow

- Cooldown and hydrate/wax formation

- Sloshing

Oil tank sloshing due to FPSO motions

Oil tank sloshing due to FPSO motions

To Learn more about how MES’ CFD expertise can help you:

Contact any of our many global offices or fill in the Enquiry Form (see red tab top left). Alternatively, you can write to us at: mes.info@mes-international.com

MES - Minimising Risk, Maximising Performance

SECTOR STUDIES

- Hazard Identification (HAZID) Workshop

- Hazard and Operability (HAZOP) Workshop

- Preliminary Hazard Analysis (PHA) Workshop

- Offshore Activities Risk Assessment Review

- BOWTIE Workshop

- Failure Modes Effects and Criticality Analysis (FMECA) Workshop

- Reliability Operability Maintenance (ROM) Workshop

- Environmental Identification (ENVID) Workshop

- Best Available Techniques (BAT) Workshop

- Safety Integrity Level (SIL) Workshop

- Layers of Protection Analysis (LOPA) Workshop

- Fire and Explosion Hazards Analysis (FERA/FEA/FRA/FEDHA)

- Gas Dispersion and Smoke Ingress (GDSI) Analysis

- Exhaust Vent Study

- Escape, Evacuation and Rescue Analysis (EERA)

- Emergency Systems Survivability Assessment (ESSA)

- Temporary Refuge Integrity Analysis (TRIA)

- Non-Hydrocarbon Hazards Analysis (NHHA)

- Dropped Object (DOS) and Material Handling Study

- Ship/Helicopter Collision and Structural Failure Study

- Transportation Risk Assessment (TRA)

- Blast and Overpressure Analysis

- Topsides/Riser/Subsea/Ship Safety Analysis

- Fire, Heat and Smoke Detection System Design

- Active Fire Protection (AFP) Design

- Passive Fire Protection (PFP) Design

- Fire and Gas Mapping

- Fire Dynamics Analysis/Fire Effects Modelling

- Quantitative Risk Assessment (QRA) for Onshore and offshore Facilities

- Offshore/Onshore Pipeline QRA

- Miscellaneous Risk Assessments (eg. Temporary Buildings, Transportation, etc.)

- Simultaneous Operations (SIMOPS) Risk Assessment

- Cost-Benefit Analysis (CBA)

- ALARP Assessment

- Offshore HSE/Safety Case Development

- Onshore COMAH/CIMAH Report Development

- HSE/Safety Case Updates/Revisions and Bridging Documents

- HSE MS Audits and Reviews

- Hazard and Risk Register Preparation

- Emergency Response Plan (ERP) Development

- Procedures for General Safety, Operations and Maintenance (SOP) Development

- Performance Standards (PS) Development for Safety Critical Elements (SCES)

- Safety Strategy and Philosophy Development

- Onshore and offshore Facilities Surveys and Audits

- Working Environment Risk Assessment (WERA)

- Human Error and Human Factor Study

- Job/Task Hazard Analysis (JHA)

- Study of Human Behaviour during MAE

- Ergonomics Study

- Environmental Impact Assessment (EIA)

- EIA Scoping

- Availability Studies

- Markov State Modelling

- Logistics and Transportation Using "Real Time" Simulation Modelling

- Debottlenecking and Performance Improvement Studies

- Spare Parts Optimisation Studies

- System Performance Evaluations

- Whole Life Cycle Costing Evaluation

- CAPEX and OPEX Economic Calculations

- Risk Based Inspection Services

- Reliability Centered Maintenance (RCM) Studies

- Maintenance Optimisation Studies

- Root Cause Analysis

- Verification and Validation

- Functional Safety Assessments

- SIS Design

- Safety Requirement Specification Development

- Functional Safety Audits

- Fundamentals of Functional Safety Training

- Safety Integrity Level (SIL) Determination Training

- Layer of Protection Analysis (LOPA) Training

- Introduction to Reliability Concepts, Principles and Applications Training

- Advanced RAM Analysis Training

- Reliability Measurement and Improvement Training